OK - this is confusing a lot of people - The Owner's manual states that we are supposed to check the Fuel Injection Synchronizing at the 1000 km/600 mile mark - and

For anyone who hasn't been following - this is a follow on from this thread....

https://www.yamahastarbolt.com/mods-and-accessories/what-did-you-do-to-your-bolt-today/60/This is similar to balancing multiple carbs, which ensures that each cylinder is working the same amount. This helps the engine run smoother and work more efficiently. On a multiple carb setup (like my old XS650 or XJ1100), there is an adjustment screw between each pair of carbs, allowing you to adjust the throttles independently, to a small extent (a tiny adjustment is all that's needed). But as Pirate has mentioned, this is a single throttle body....

Almost....

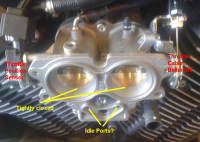

Here's a pic of the throttle body.....

As you can see - it's set up like a 2-barrel carb - 2 separate throttle plates on a single shaft (with the cables at the front end and the Sensor at the back). You can also see that the throttle plates are tightly sealed, unlike a carburetor would be. Carbs let air leak past the throttle plates at a small rate to set the idle. Adjusting this gap sets the idle speed and adjusts the balance if you adjust the plates differently.

EFI does it differently - it seals the throttle plates tightly closed and has a small port that the computer can open and close to control idle speed - that's how it can set fast idle when it needs to warm up the engine without having to move the throttle plates. The 2 small holes below the throttles are the idle ports.

Soooooo - now that we have an idea WHAT the parts are, what they do, and how..... The question is .... How do we check and adjust it?

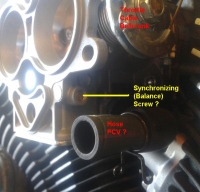

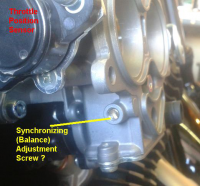

The method to adjust them is on the sides of the Throttle Body...... One on the Right and one on the Left

There's one screw on each side, one for each cylinder.

How to CHECK the balance, however is pretty simple.....

As I'd said in the other thread, the best way to check the synch is probably the cheapest - the $1.55 carb balancer tool found here

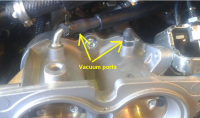

http://www.powerchutes.com/manometer.asp. Basically, it's just a long piece of clear plastic tubing with a little red transmission fluid in it (maybe a tablespoon or two depending on the size of tubing). Connect one end to each of the vacuum ports on the throttle body, and find something high to toss it over and let it hang. I just toss it over the rafters of my garage (with the door open, of course - Carbon monoxide is DEADLY), with a weight at the center so it hangs down. You only want a couple feet of the tubing to have fluid in it - don't fill it up - you want to see the levels moving. Vacuum ports? Check on the top of the Throttle Body.....

Right on top where they're easy to get to. The vacuum hose from the rear leads up under the tank. It's the vacuum that holds the fuel valve open, so you'll have to TEE into it or your engine will die with no fuel.

Anyway.... install a T - and take the cover off the forward vacuum barb (DON'T LOSE IT!), and connect the plastic tubing to the ports. Which one goes where isn't important, but a good seal is. I'm not sure what size the barbs are, but that would be a good way to get your tubing - to match the ports. Try to keep the tubing as far away from the cylinders as possible - we don't want them to melt and make a nasty mess all over your new bike!

Here's kind of how it looks -

He's got the tubing with the trans fluid in it where he can see it - with the tubing going high and down to his carbs - in our case - down to the throttle bodies.

Then all you have to do is Start the engine! VOILA!

If the fluid moves to one side, and keeps going - you'll need to synch the system. If it stays reasonably steady - you're good to go!

In any case - it shouldn't be too bad, since they are pretty new from the factory.

In the pic above - check how close the levels in the tube are - then check the tach (on the right) - his bike is running at 1250 rpm, and the levels are dead even! PERFECT synch!

The setup is SUPER Sensitive (MUCH more sensitive than ANY gauge setup could ever hope), so there is a chance it could suck the trans fluid into your engine before you an shut it down (but only if it's REALLY out to lunch). DON'T PANIC! It may smoke out your garage and make a big stink, but it WON'T do any damage to your bike. That's why we use Transmission oil - it's easy to see in the tube, but it's just oil, and will burn out with no damage.

A TINY adjustment is all it should need to bring the system back into balance, and your bike running top-notch again.

Your Privacy Choices

Your Privacy Choices